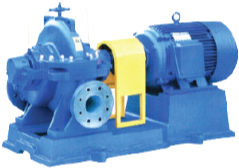

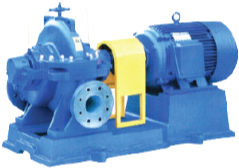

THSC SERIES

Waterworks, irrigation and drainage pumping stations. Power stations, industrial water supply systems, fire fighting applications in refineries

OPERATING DATA

| Pump sizes |

DN 80 |

up |

to |

900mm |

| Capacities |

Q |

up |

to |

5000I/s |

| Total heads |

H |

up |

to |

200m |

| Operating pressure |

P |

up |

to |

30bar |

| Operating temperature |

I |

up |

to |

+105°C |

MODEL CODE

| Series : |

THSC |

| Suction (mm) : |

200 |

| Discharge (mm) : |

125 |

| Nominal Impeller diameter (mm) : |

290 |

| Vertical type : |

v |

TRE SERIES

The Trosx Series TRE series fully conforms to the pump standard DIN EN 733 (formerly DIN 24255) and covers all sizes nominated. This makes the range fully interchangeable with other brands of pump designed to this standard.

‘BACK PULLOUT’ FEATURE

| • |

If spaces coupling is installed, pump can be separated

from the driver without having to dismantle the driver or

pump the common skid. |

| • |

Bearing housing assembly can be removed for repair or servicing without having to disturb the connected piping. |

WORKING PRESSURE

Maximum pressure rating to 16 bar

(Some models operating at 10 bar)

CAPACITY

Capacity range up to maximum of 330 litres/sec (1200m³/hr)

DISCHARGE PRESSURE

Discharge pressure range up to maximum of 150 metres

(15 bar)

SPEED OF ROTATION

Maximum operating speed up to 3500 r.p.m

PUMPED LIQUID

Clean, without solid or abrasive substances, not viscous not aggressive, not crystallized and chemically neutral, close to water characteristics.

LIQUID TEMPERATURE RANGE

From -10° + 0 + 140°C

SPECIAL VERSIONS ON REQUEST

Pumps for liquids other than water other voltages and / or frequencies.

TSP SERIES

TSP Non-clogging self-priming sewage pump is our latest developed product, and is suitable for the treatment project of municipal sewage and industrial sewage as well as stage treatment and concentrated treatment system of various sewages. It’s known as “King of Self-Priming Sewage Pump”, and the most ideal new-generation sewage product.

APPLICATION

| • |

Non-flammable and non-explosive liquid |

| • |

Rain water and common sewage |

| • |

Municipal drainage project, construction site, drainage

station of people’s air defence system |

| • |

Industrial sewage of light industry, paper mill, textile, food processing plant, chemical industry, electric utility, deep mines etc |

| • |

Sewage discharge in the residential area |

| • |

Sewage and deposit of water purifying system |

| • |

Tanning industry, sewage of slaughter house, fish breeding in the river and pond |

| • |

Wind and sugar industry |

| • |

Sewage discharge not having strong corrosiveness but seriously polluted |

MODEL CODE

| Self-priming sewage pump : |

TSP |

| Inlet and outlet: 4” (Φ100 mm) : |

4 |

Operating Condition

| • |

Liquid temperature: 0°C – 40°C, medium density ≤1.2 x 103

kg/m3 , PH5-9 |

| • |

Volume ratio of solids in the medium ≤ 2% |

| • |

Diameter of maximum grain free pass: TSP-2: 38 mm TSP-3: 63 mm TSP-4 to TSP-10: 76 mm |

| • |

Ambient temperature: ≤ 40°C |

| • |

Altitude: Max. 1, 000 m |

| • |

Max working pressure: see Performance Curve |

| • |

Max Suction head: see Performance Table |

Reviews

There are no reviews yet.