Uncategorized

Showing all 8 results

-

DUCKBILL SERIES

Trosx duckbill check valve and perfectly design for flood control & protect discharge line back flow, especially from rising of water level & also to ensure storm water does not back flow back to catchment areaRead more1.PUMPED LIQUIDS

Thin, non-explosive liquids, not containing solid particles. The liquid must not attack the pump materials chemically. When pumping liquids with a density or viscosity higher than that of water, motor with correspondingly higher outputs must be used, if required.ADVANTAGE OF DESIGN:

q. 100% elastomer construction b. No moving parts c. Minimum maintenance cost d. Low cracking pressure e. Low pressure loss f. No rust or corrode g. Will not warp or freeze open or shut down h. Self-draining & eliminate standing water i. Prevent back flow j. Non slam design, silent operationWORKING PRINCIPLE:

Whenever the valve inlet exceeded back pressure at the outlet valve, the flow mechanism will be created, as show above.

When the backpressure exceeded the line pressure, the duckbill will be closed automatically and prevent back flow.

APPLICATION & INSTALLATION:

a. Sewer application b. Flood control c. Pumping line d. Mining tailing systems e. Dredging f. Scrubber systems g. We/dry wallMATERIAL OF CONSTRUCTIONS & APPLICATION:

• EPDM – water, weak acid, ozone and some hydrocarbon • NBR (Buna-N) – Oily water & waste water, fats, moderate chemical & grease waste water • Natural Rubber (NR) – Alcohols, organics acid, ketones, moderate acid & abrasive waste water • Hypalon (CSM) – Strong acids, ozone, oxidizing chemicals • Neoprene (CR) – Oily water, grease and fats • Viton (FKM) – Aromatic, solvents, halogenated, hydrocarbon, acid & oils -

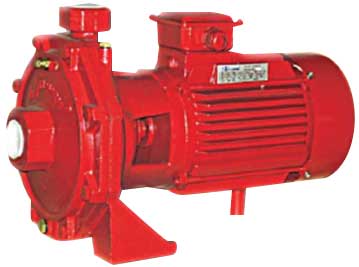

TDE SERIES

For clean liquids without abrasions which are non-aggressive for the pump materials. For fire fighting.For water supply.Read moreAPPLICATIONS

• For clean liquids without abrasions which are non-aggressive for the pump materials • For fire fighting • For water supply PUMP

• Cast Iron pump body • Bronze Impeller • Mechanical Seal • Liquid temperature up to 90ºC • Total suction lifts up to 5 Meters • Max working pressure 10 Bars -

TFG SERIES

The TFG series are with two back to back impellers (with axial thrust balancing). It uses is ideal for high head values where single impeller types are hard to reach. Suitable for civil and industrial boosting, firefighting plant, flood irrigations, etc. it uses to pump clean water and chemically non-aggressive liquid. Particularly be used for increasing the supply pressure, feeding boilers and loading extremely. These pumps should be installed in a covered area, protected against the weather.Read moreGENERAL

Pump body : Cast iron Impeller : Brass Motor : Closed, Externally ventilated Insulation class : F Protection class : IP54 Duty : Continuously rated Mechanical seal Ø16, Ø18, Ø25 Ceramic steatite / Graphite Shaft Stainless steel AISI 420 -

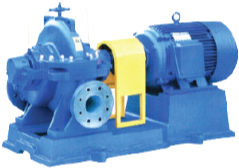

THSC SERIES

Waterworks, irrigation and drainage pumping stations. Power stations, industrial water supply systems, fire fighting applications in refineriesRead moreOPERATING DATA

Pump sizes DN 80 up to 900mm Capacities Q up to 5000I/s Total heads H up to 200m Operating pressure P up to 30bar Operating temperature I up to +105°C MODEL CODE

Series : THSC Suction (mm) : 200 Discharge (mm) : 125 Nominal Impeller diameter (mm) : 290 Vertical type : v -

TRE SERIES

The Trosx Series TRE series fully conforms to the pump standard DIN EN 733 (formerly DIN 24255) and covers all sizes nominated. This makes the range fully interchangeable with other brands of pump designed to this standard.Read more‘BACK PULLOUT’ FEATURE

• If spaces coupling is installed, pump can be separated from the driver without having to dismantle the driver or pump the common skid. • Bearing housing assembly can be removed for repair or servicing without having to disturb the connected piping. WORKING PRESSURE

Maximum pressure rating to 16 bar (Some models operating at 10 bar)CAPACITY

Capacity range up to maximum of 330 litres/sec (1200m³/hr)DISCHARGE PRESSURE

Discharge pressure range up to maximum of 150 metres (15 bar)SPEED OF ROTATION

Maximum operating speed up to 3500 r.p.mPUMPED LIQUID

Clean, without solid or abrasive substances, not viscous not aggressive, not crystallized and chemically neutral, close to water characteristics.LIQUID TEMPERATURE RANGE

From -10° + 0 + 140°CSPECIAL VERSIONS ON REQUEST

Pumps for liquids other than water other voltages and / or frequencies. -

TRX SERIES

TRX vertical multistage in-line stainless steel centrifugal pumps are designed for the following applications:Read more1.PUMPED LIQUIDS

Thin, non-explosive liquids, not containing solid particles. The liquid must not attack the pump materials chemically. When pumping liquids with a density or viscosity higher than that of water, motor with correspondingly higher outputs must be used, if required.2.APPLICATION

• Municipal water supply and pressure boosting • Domestic water supply • Boiler feed and condensate systems • Cooling water systems • Irrigation and dewatering • Fire fightingWashing plants and washdownMODEL CODE

Series TRX = 50hz Vertical Multistage Stainless steel pump : TRX Nominal flow in m³/h : 200 Number of stage x10 : 40 2 small impeller A : 2A 1 small impeller B : B TECHNICAL DATA

1 Ambient Temperature Maximum : +40°C 2 Liquid Temperature Standard design: -15°C to +90°C (Max) For hot water design: -15°C to +120°C 3 Min suction pressure According to NPSH add 0.5m water head 4 Electric Motor standard be supplied as: 50HZ, single phase 220V~240V or three phase 380V~415V, aluminum casing, IP55, class F. 60Hz, single phase 110V or three phase 220V, aluminum casing, IP55, class F. NEMA standard motor on request. 5 Pump’s material can be supplied in 304, 316 or 316L stainless steel -

TSP SERIES

TSP Non-clogging self-priming sewage pump is our latest developed product, and is suitable for the treatment project of municipal sewage and industrial sewage as well as stage treatment and concentrated treatment system of various sewages. It’s known as “King of Self-Priming Sewage Pump”, and the most ideal new-generation sewage product.Read moreAPPLICATION

• Non-flammable and non-explosive liquid • Rain water and common sewage • Municipal drainage project, construction site, drainage station of people’s air defence system • Industrial sewage of light industry, paper mill, textile, food processing plant, chemical industry, electric utility, deep mines etc • Sewage discharge in the residential area • Sewage and deposit of water purifying system • Tanning industry, sewage of slaughter house, fish breeding in the river and pond • Wind and sugar industry • Sewage discharge not having strong corrosiveness but seriously polluted MODEL CODE

Self-priming sewage pump : TSP Inlet and outlet: 4” (Φ100 mm) : 4 Operating Condition

• Liquid temperature: 0°C – 40°C, medium density ≤1.2 x 103 kg/m3 , PH5-9 • Volume ratio of solids in the medium ≤ 2% • Diameter of maximum grain free pass: TSP-2: 38 mm TSP-3: 63 mm TSP-4 to TSP-10: 76 mm • Ambient temperature: ≤ 40°C • Altitude: Max. 1, 000 m • Max working pressure: see Performance Curve • Max Suction head: see Performance Table -

TVI (BGI) SERIES

Close-coupled, single-impeller, centrifugal pumps electric motor with directly connected to the pump.Pump casing with suction and delivery connections with the same diameter and on the same axis (in-line)Read moreAPPLICATIONS

• For clean liquids, without abrasives, which are non-aggressive for the pump materials (contents of solid up to 0.2 %) • For heating, conditioning, cooling and circulation plants • For civil and industrial applications OPERATING CONDITIONS

• Liquid temperature up to 90°C • Ambient temperature up to 40° • Total suction lift up to 7 meter • Maximum permissible working pressure up to 10 bar • Continuous duty • Three phase 415 V/50 Hz induction Motor • Insulation class F • Protection IP54