DUCKBILL SERIES

Trosx duckbill check valve and perfectly design for flood control & protect discharge line back flow, especially from rising of water level & also to ensure storm water does not back flow back to catchment area

1.PUMPED LIQUIDS

Thin, non-explosive liquids, not containing solid particles. The liquid must not attack the pump materials chemically. When pumping liquids with a density or viscosity higher than that of water, motor with correspondingly higher outputs must be used, if required.

ADVANTAGE OF DESIGN:

q. 100% elastomer construction

b. No moving parts

c. Minimum maintenance cost

d. Low cracking pressure

e. Low pressure loss

f. No rust or corrode

g. Will not warp or freeze open or shut down

h. Self-draining & eliminate standing water

i. Prevent back flow

j. Non slam design, silent operation

WORKING PRINCIPLE:

Whenever the valve inlet exceeded back pressure at the outlet valve, the flow mechanism will be created, as show above.

When the backpressure exceeded the line pressure, the duckbill will be closed automatically and prevent back flow.

APPLICATION & INSTALLATION:

a. Sewer application

b. Flood control

c. Pumping line

d. Mining tailing systems

e. Dredging

f. Scrubber systems

g. We/dry wall

MATERIAL OF CONSTRUCTIONS & APPLICATION:

| • |

EPDM – water, weak acid, ozone and some hydrocarbon |

| • |

NBR (Buna-N) – Oily water & waste water, fats, moderate

chemical & grease waste water |

| • |

Natural Rubber (NR) – Alcohols, organics acid, ketones,

moderate acid & abrasive waste water |

| • |

Hypalon (CSM) – Strong acids, ozone, oxidizing chemicals |

| • |

Neoprene (CR) – Oily water, grease and fats |

| • |

Viton (FKM) – Aromatic, solvents, halogenated, hydrocarbon,

acid & oils |

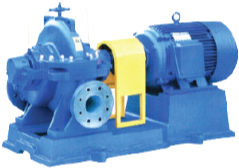

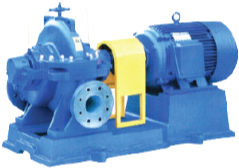

THSC SERIES

Waterworks, irrigation and drainage pumping stations. Power stations, industrial water supply systems, fire fighting applications in refineries

OPERATING DATA

| Pump sizes |

DN 80 |

up |

to |

900mm |

| Capacities |

Q |

up |

to |

5000I/s |

| Total heads |

H |

up |

to |

200m |

| Operating pressure |

P |

up |

to |

30bar |

| Operating temperature |

I |

up |

to |

+105°C |

MODEL CODE

| Series : |

THSC |

| Suction (mm) : |

200 |

| Discharge (mm) : |

125 |

| Nominal Impeller diameter (mm) : |

290 |

| Vertical type : |

v |

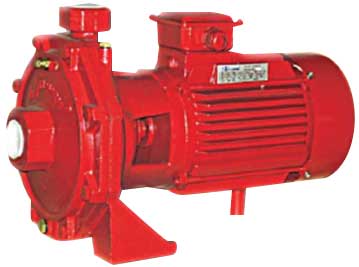

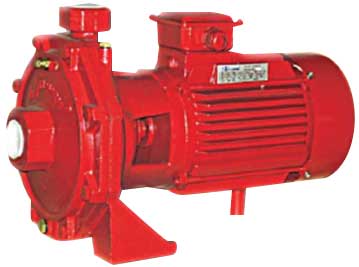

TFG SERIES

The TFG series are with two back to back impellers (with axial thrust balancing). It uses is ideal for high head values where single impeller types are hard to reach. Suitable for civil and industrial boosting, firefighting plant, flood irrigations, etc. it uses to pump clean water and chemically non-aggressive liquid. Particularly be used for increasing the supply pressure, feeding boilers and loading extremely. These pumps should be installed in a covered area, protected against the weather.

GENERAL

| Pump body : |

Cast iron |

| Impeller : |

Brass |

| Motor : |

Closed, Externally ventilated |

| Insulation class : |

F |

| Protection class : |

IP54 |

| Duty : |

Continuously rated |

| Mechanical seal |

Ø16, Ø18, Ø25 Ceramic steatite / Graphite |

| Shaft |

Stainless steel AISI 420 |

Reviews

There are no reviews yet.